Inkcazo

Iisarha zeCarbide zidla ngokusetyenziswa kwiisarha ezinje ngeesarha zesandla esisetyhula, iisarha zemiter kunye neesarha zetafile ezisisigxina.Iincinci ezincinci zentsimbi ye-carbide zikhuselekile kwintsimbi ejikelezayo.I-epoxy yokumelana nobushushu obuphezulu isetyenziselwa ukubamba amazinyo e-carbide endaweni.Amazinyo eCarbide anenzuzo yokuba nzima kakhulu, ngoko angakwazi ukugcina umgca obukhali ixesha elide

1. Amabanga: YG6X,YG6,YG8,YG8X,JX10,JX15,JX35,JX40 njl.

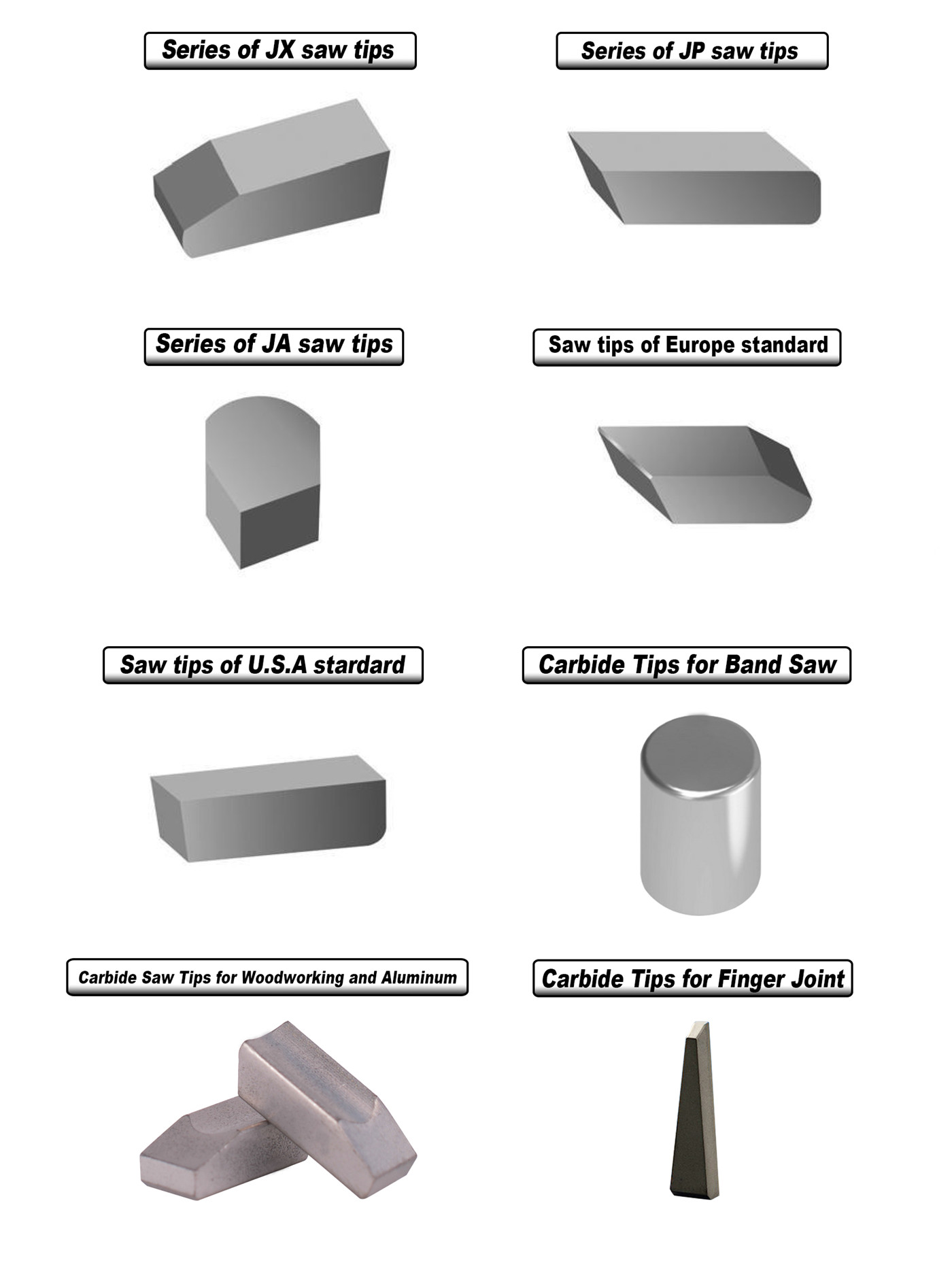

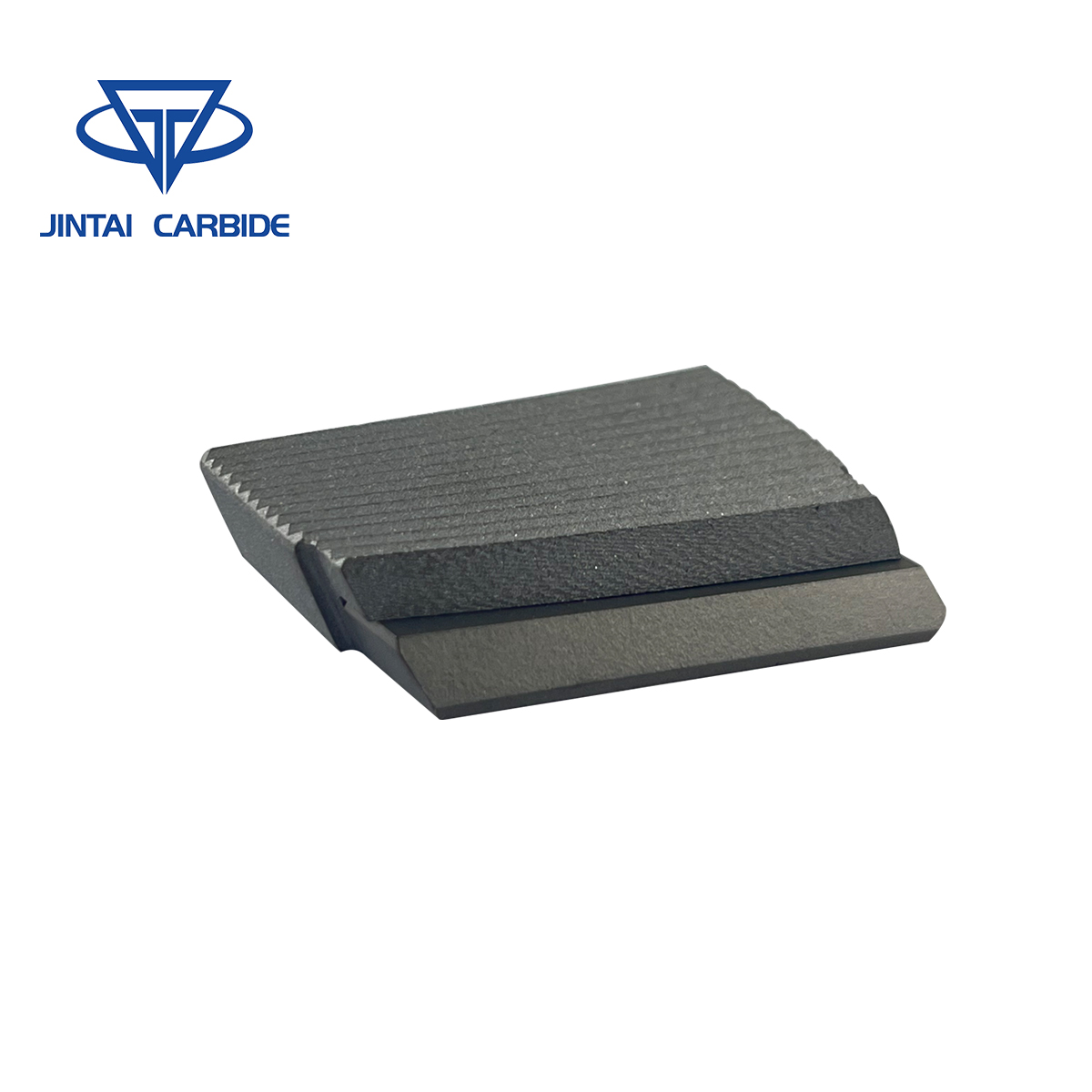

2. iingcebiso isarha ziquka JX series, JP series, JA series, USA Standard and European Standard njl.

3. Zonke iingcebiso zabona i-HIP-Sintered, ukuqinisekisa umgangatho ophezulu, ngokucinezela ngokuzenzekelayo ukuqinisekisa ubungakanani obuchanekileyo, i-tumble kunye ne-nickel egqunyiweyo ukuqinisekisa ukusebenza kakuhle kwe-brazing.

4. Uphawu lwethu lufumana udumo oluvela kubathengi baseYurophu, eU.SA, eAsia, njl.

5. Amabakala ethu agubungela lonke uluhlu lwe-ISO, olulungele ukucheba ingca, umthi oqinileyo, iinkuni ezisetyenzisiweyo, isinyithi, iplastiki, iPVC, iMDF, ibhodi yeMelamine, iplywood, njl.

Ukuqina okuphezulu kunye nokumelana nokuqhekeka, ii-saw blades zethu zenzelwe ukuzinza nokuthembeka.Nokuba yeyiphi na imathiriyeli oyisikayo, iiblade zethu ziya kuhlala zisenza umsebenzi oncomekayo.Nokuba ngamaplanga, yintsimbi, okanye iplastiki, iisarha zethu zityibilika ngaphandle kokuzama ukukunika ukusikwa okugqibeleleyo ngalo lonke ixesha.

Ezi zifakelo zibonakalisa ubunzima obuphezulu, ukuxhathisa ukuphuka kunye nenkqubo ye-HIP ye-sintering eqinisekisa ukuzinza, ukuthembeka kunye nokunqunyulwa kwexesha elide.Imveliso yethu ye-automated ye-state-of-art iqinisekisa umgangatho ohambelanayo kunye nempumelelo enkulu, ngelixa inkxaso yethu yoluhlu olubanzi lweenkcukacha kunye neendlela zokwenza ngokwezifiso zihlangabezana nazo zonke iimfuno zakho zokusika ezahlukeneyo.

Vula amandla okusika eTungsten Carbide Saw Tips!Njengomntu othanda i-e-commerce ewela umda, ufike kwindawo elungileyo yeengcebiso zeTungsten Carbide Saw ezigqwesileyo kwizicelo ezahlukeneyo zokusika, eqinisekisa ukusebenza okugqwesileyo kunye nobomi obandisiweyo.

Iinjineli zethu ze-Tungsten Carbide Saw Tips ziqhayisa ngobulukhuni obukhethekileyo kunye nokumelana nokunxiba, nto leyo ezenza zibe lolona khetho lubalaseleyo lomsebenzi wokusarha ekwenzeni amaplanga, ukwenza isinyithi, nokunye.Bala ezi ngcebiso ukuhambisa ukusikwa okuchanekileyo kunye nokuqina okungenakulinganiswa, ukuguqula iinkqubo zakho zokusika.

Hayi nje ukuqina, iingcebiso zethu ze-Tungsten Carbide Saw Saw zibonisa ukuxhathisa ubushushu obukhethekileyo, iqinisekisa ukusebenza okungaguqukiyo nakwindawo ezinobushushu obuphezulu.Amava amandla abo okugcina ubukhali kunye nokuthembeka, kukuvumela ukuba ukhulise imveliso kwaye unciphise ixesha lokuphumla.

E-JINTAI, siyazingca ngokuzisa iimveliso ezihlangabezana nemigangatho ephezulu yomgangatho.I-Tungsten Carbide Saw Tip nganye ivavanywa ngokungqongqo, iqinisekisa ukungaguquguquki kunye nokugqwesa, ikuxhobisa ukuba ufezekise iziphumo ezimangalisayo kwiiprojekthi zakho zokusika.

Yamkela ukusebenza kakuhle kunye nokusebenza kakuhle ngexabiso lethu leprimiyamu yeeNgcebiso zeTungsten Carbide Saw, kwaye ufumane umda wokukhuphisana kwishishini lakho.Sebenzisana nathi namhlanje ukuze ube namava okusebenza ngokungenakuthelekiswa nanto ezi ngcebiso zizisa kwimisebenzi yakho yokusika.

Khetha i-JINTAI yokuthembeka, ukusebenza okuphezulu kweeNgcebiso ze-Tungsten Carbide Saw, kwaye babone amandla abo okwenene ekunyuseni ishishini lakho ukuya kwiindawo eziphakamileyo.Faka iodolo yakho ngoku kwaye usebenzise amandla ezisombululo zethu ezikumgangatho ophezulu.

Uluhlu lweBanga

| IBanga | ISO Code | iiPropathi zoomatshini boMzimba (≥) | Isicelo | ||

| Ukuxinana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining yentsimbi kunye neentsimbi ezingenayo i-ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ilungele ukuchaneka kwe-machining kunye nokugqitywa kwesiqingatha sentsimbi etyhidiweyo kunye neentsimbi ezingenayo i-ferrous, kunye nokulungiswa kwentsimbi yemanganese kunye nentsimbi ecinyiweyo. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ilungele ukugqitywa kwe-semi-ukugqiba kunye ne-rough machining yentsimbi etyhidiweyo kunye ne-alloys ekhanyayo, kwaye ingasetyenziselwa ukucwangciswa kwentsimbi kunye nentsimbi ephantsi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanelekile ukugrumba ilitye elijikelezayo kunye ne-rotary impact drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele ukulayita okumile okwetshizili okanye amasuntswana amazinyo angama-conical koomatshini bokwemba amatye obunzima bokujongana nokwakheka kwamatye aqinileyo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanelekile ukuvavanywa kwe-tensile yeentsimbi zetsimbi kunye nemibhobho yensimbi phantsi koxinzelelo oluphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ilungele ukwenza isitampu iifa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ilungele ukwenza isitampu esibandayo kunye nokucofa okubandayo kumashishini anje ngeendawo eziqhelekileyo, iibheringi, izixhobo, njl. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yensimbi engenasici kunye nentsimbi ye-alloy jikelele. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanelekile kwi-semi-finishing yensimbi engenasici kunye nentsimbi ephantsi ye-alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanelekile ukuchaneka kwe-iron-based based, i-nickel-based high-temperature alloys, kunye nentsimbi ephezulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanelekile ukusika intsimbi enzima kunye nentsimbi. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanelekile ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi yokuphosa, kunye nesantya sokutya esiphakathi.I-YS25 yenzelwe ngokukodwa imisebenzi yokugaya kwintsimbi kunye nentsimbi. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ilungele izixhobo zokusika ezinzima, ezibonelela ngeziphumo ezigqwesileyo ekujikeni ngokurhabaxa kwe-castings kunye neentlobo ezahlukeneyo zentsimbi. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele ukulayita amasuntswana okugrumba amatye ajikelezayo kunye nokugrumba kulwakhiwo oluqinileyo noluqina noko. |

Inkqubo yoku-odola

Inkqubo yeMveliso

Ukupakishwa

-

I-Tungsten Carbide iyasweleka-Ukunyathela kuFa kwaye...

-

Ingcebiso yeTungsten Carbide yokuSebenza ngamaplanga kunye ne-STB

-

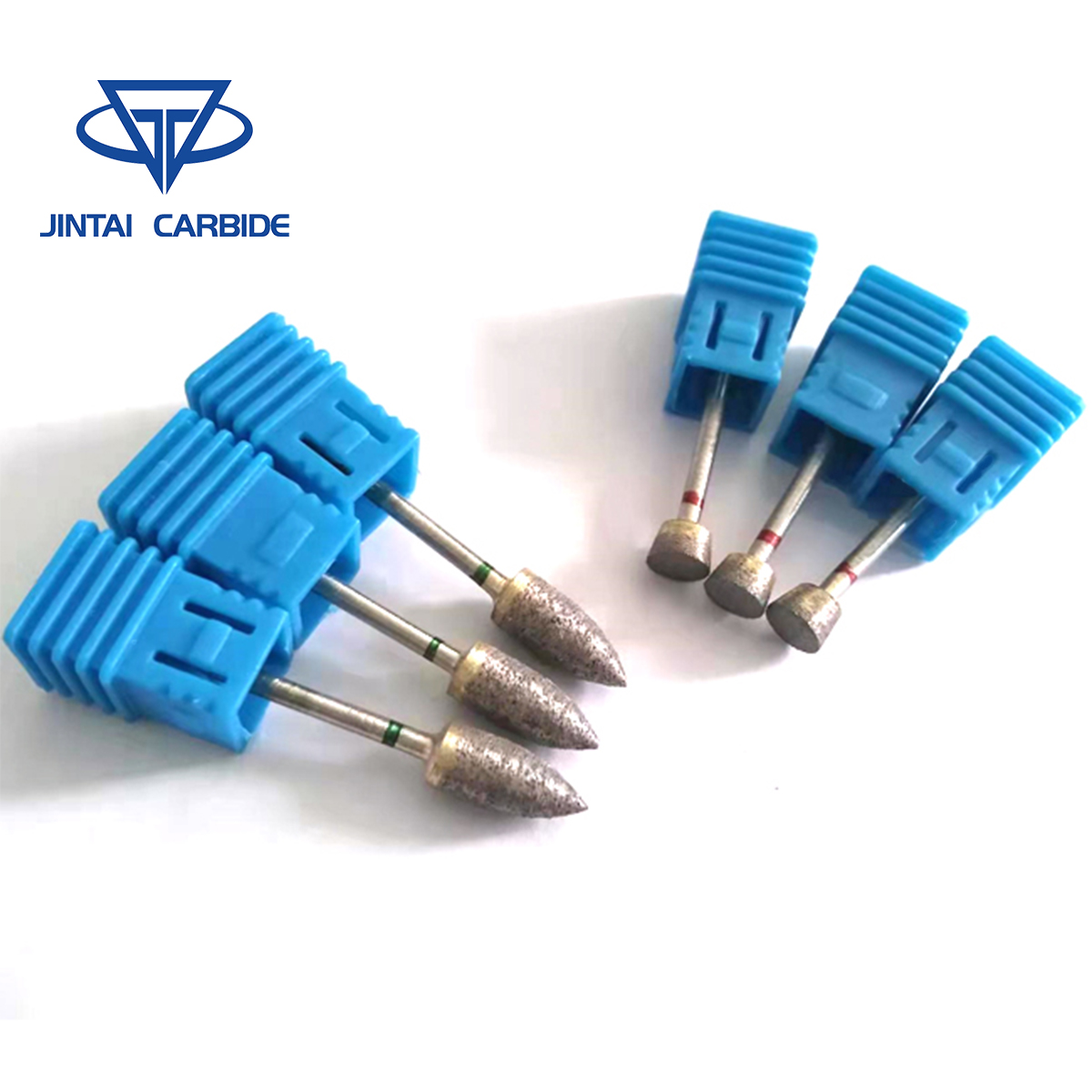

Tungsten Carbide Rotary Burr Okanye Die Grinder Bits

-

I-Tungsten Carbide Fiber Optic Cleaver Replacemen...

-

Tungsten Carbide ISO Standard Brazed Tips

-

ITungsten Carbide Scalping Cutter yeCopper kunye...