Inkcazo

1.Ii-flash edges ezichetywayo, ii-burrs kunye nemigca ye-welding ye-casting, i-forging kunye ne-welding parts;

2.Gqibezela machining iintlobo ezahlukeneyo zokubumba isinyithi;

3.Ukugqiba iingcango ezityhidiweyo zevili elinevili;

4.I-Chamfering, ukujikeleza kunye nokuhanjiswa kweentlobo ezahlukeneyo zamalungu oomatshini;

5.Gqiba ukwenza ubuchwephesha kumphezulu wangaphakathi wamalungu oomatshini;

6. Ukukrolwa kobugcisa bazo zonke iintlobo zentsimbi okanye iindawo ezingezizo ezentsimbi.

7. I-Tungsten Carbide yinto eyongezelelweyo yokumelana nokunxiba enokuthi iphunyezwe kuzo zombini iindawo ezihambayo kunye ne-static. Le yimeko ekhethekileyo kwiimeko zenkonzo, ezifana nobushushu obuphezulu, kunye namazinga aphezulu okubola kunye nokukrazula.

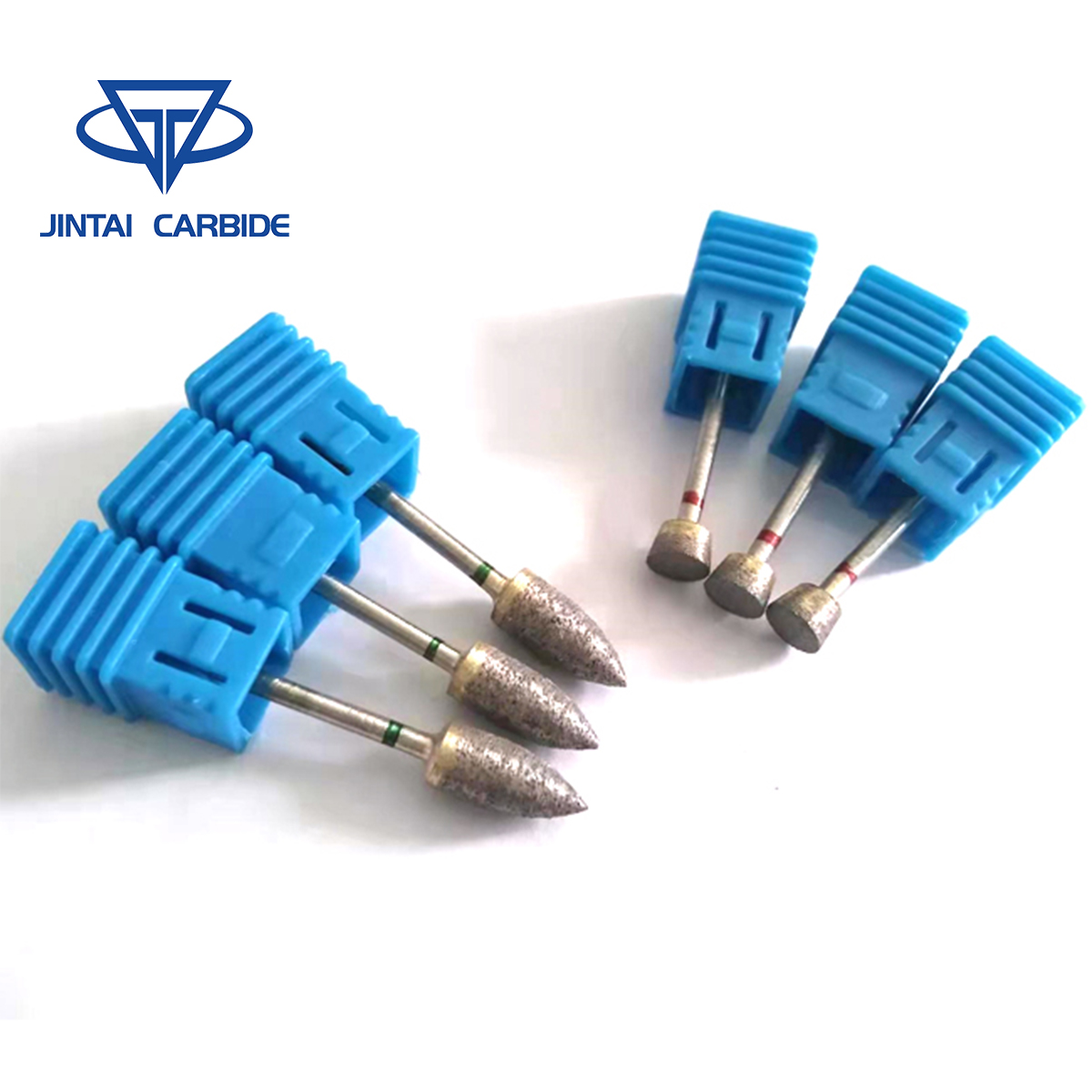

Umboniso weMveliso

SA

SB

SC

SD

SE

SF

SG

SH

SJ

SK

SL

SM

SN

Uluhlu lweBanga

| IBanga | ISO Code | iiPropathi zoomatshini boMzimba (≥) | Isicelo | ||

| Ukuxinana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining yentsimbi kunye neentsimbi ezingenayo i-ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ilungele ukuchaneka kwe-machining kunye nokugqitywa kwesiqingatha sentsimbi etyhidiweyo kunye neentsimbi ezingenayo i-ferrous, kunye nokulungiswa kwentsimbi yemanganese kunye nentsimbi ecinyiweyo. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ilungele ukugqitywa kwe-semi-ukugqiba kunye ne-rough machining yentsimbi etyhidiweyo kunye ne-alloys ekhanyayo, kwaye ingasetyenziselwa ukucwangciswa kwentsimbi kunye nentsimbi ephantsi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanelekile ukugrumba ilitye elijikelezayo kunye ne-rotary impact drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele ukulayita okumile okwetshizili okanye amasuntswana amazinyo angama-conical koomatshini bokwemba amatye obunzima bokujongana nokwakheka kwamatye aqinileyo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanelekile ukuvavanywa kwe-tensile yeentsimbi zetsimbi kunye nemibhobho yensimbi phantsi koxinzelelo oluphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ilungele ukwenza isitampu iifa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ilungele ukwenza isitampu esibandayo kunye nokucofa okubandayo kumashishini anje ngeendawo eziqhelekileyo, iibheringi, izixhobo, njl. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yensimbi engenasici kunye nentsimbi ye-alloy jikelele. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanelekile kwi-semi-finishing yensimbi engenasici kunye nentsimbi ephantsi ye-alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanelekile ukuchaneka kwe-iron-based based, i-nickel-based high-temperature alloys, kunye nentsimbi ephezulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanelekile ukusika intsimbi enzima kunye nentsimbi. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanelekile ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi yokuphosa, kunye nesantya sokutya esiphakathi.I-YS25 yenzelwe ngokukodwa imisebenzi yokugaya kwintsimbi kunye nentsimbi. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ilungele izixhobo zokusika ezinzima, ezibonelela ngeziphumo ezigqwesileyo ekujikeni ngokurhabaxa kwe-castings kunye neentlobo ezahlukeneyo zentsimbi. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele ukulayita amasuntswana okugrumba amatye ajikelezayo kunye nokugrumba kulwakhiwo oluqinileyo noluqina noko. |

Inkqubo yoku-odola

Inkqubo yeMveliso

Ukupakishwa

-

I-Tungsten Carbide Fiber Optic Cleaver Replacemen...

-

I-Tungsten Carbide Rod & Blanks OEM ODM Ava...

-

I-Tungsten Carbide Surface Milling Insets ye-Al...

-

Ingcebiso yeTungsten Carbide yokuSebenza ngamaplanga kunye ne-STB

-

Ipleyiti yeTungsten Carbide-Igudiswe kakuhle Cu...

-

ITungsten Carbide Imilo eSiko kunye neeFom