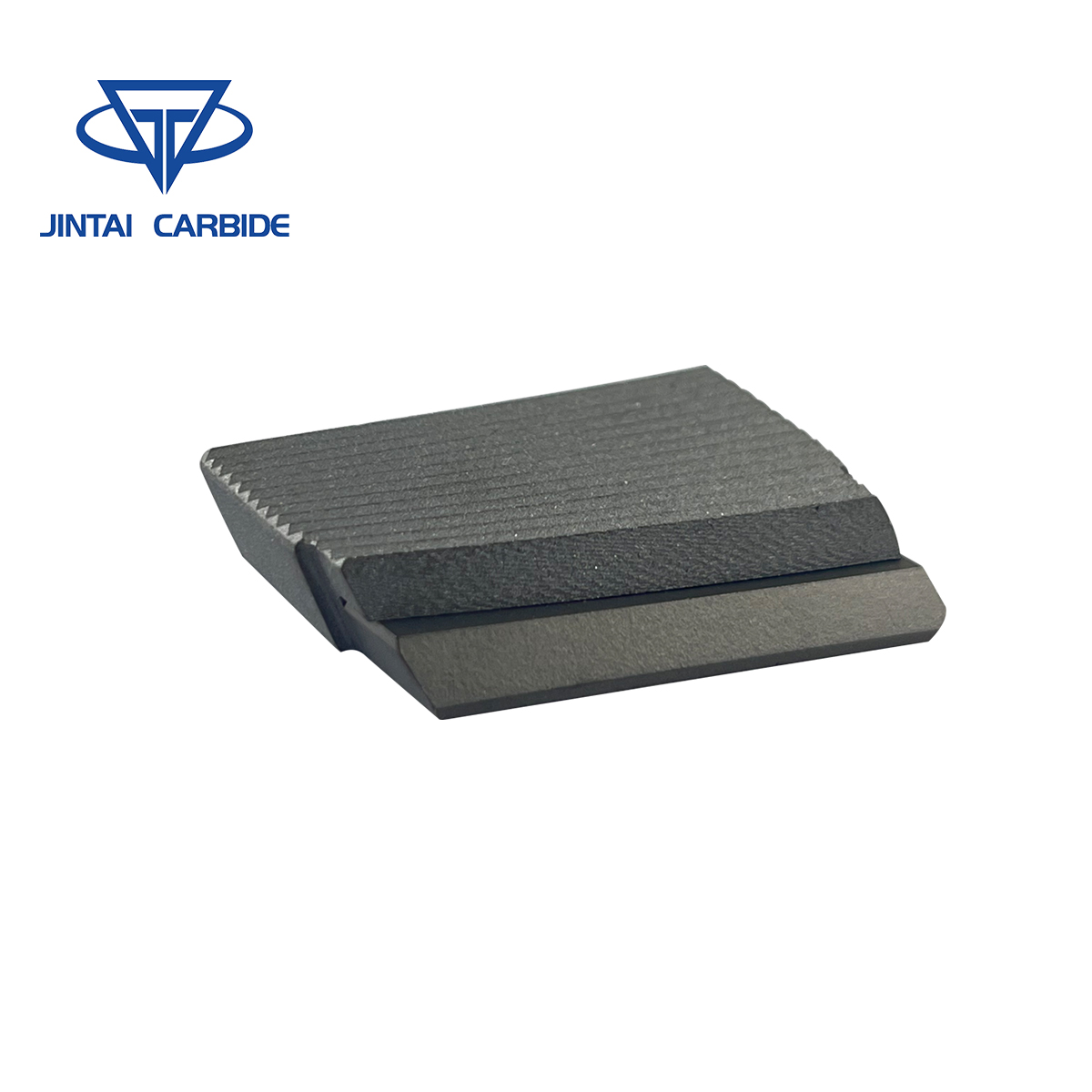

Inkcazo

"JinUTai" uyafa kwaye intloko ebandayo iyafa

Iimbonakalo:

Khetha ibakala elifanelekileyo ngokusekwe kusetyenziso lwenyani lomthengi kunye nezinto ezilungiswayo.Ngamabakala ahlukeneyo e-tungsten steel stamping die, inokuhlangabezana neemfuno zezicelo ezahlukeneyo, iinkcukacha ezipheleleyo, imilinganiselo engenanto echanekileyo, ukunciphisa umthamo wokucubungula, kunye nokuphucula ukusebenza kakuhle kunye nokusebenza kakuhle kweendleko.

Ukusebenza:

Ukusebenzisa i-99.95% yezinto ezicocekileyo ze-tungsten carbide powder kunye ne-cobalt, ubunzima bentloko ebandayo bufa bufikelela ngaphezu kwe-HRA88, amandla okugoba angaphezulu kwe-2400, ngokuqina okubomvu okugqwesileyo, ukumelana nokunxiba okuphezulu, imodyuli ephezulu, ukugoba okuphezulu, kunye nokumelana nefuthe elihlala ixesha elide. .

Usetyenziso:

Ifanele isihloko esibandayo kunye nokugqithiswa okubandayo kweendawo eziqhelekileyo ezenziwe ngobhedu, i-aluminiyam, intsimbi, izinto zentsimbi yealloyi, ezifana nezikrufu, iirivets, njl njl. kufa, intonga yokunciphisa iyafa, njl.

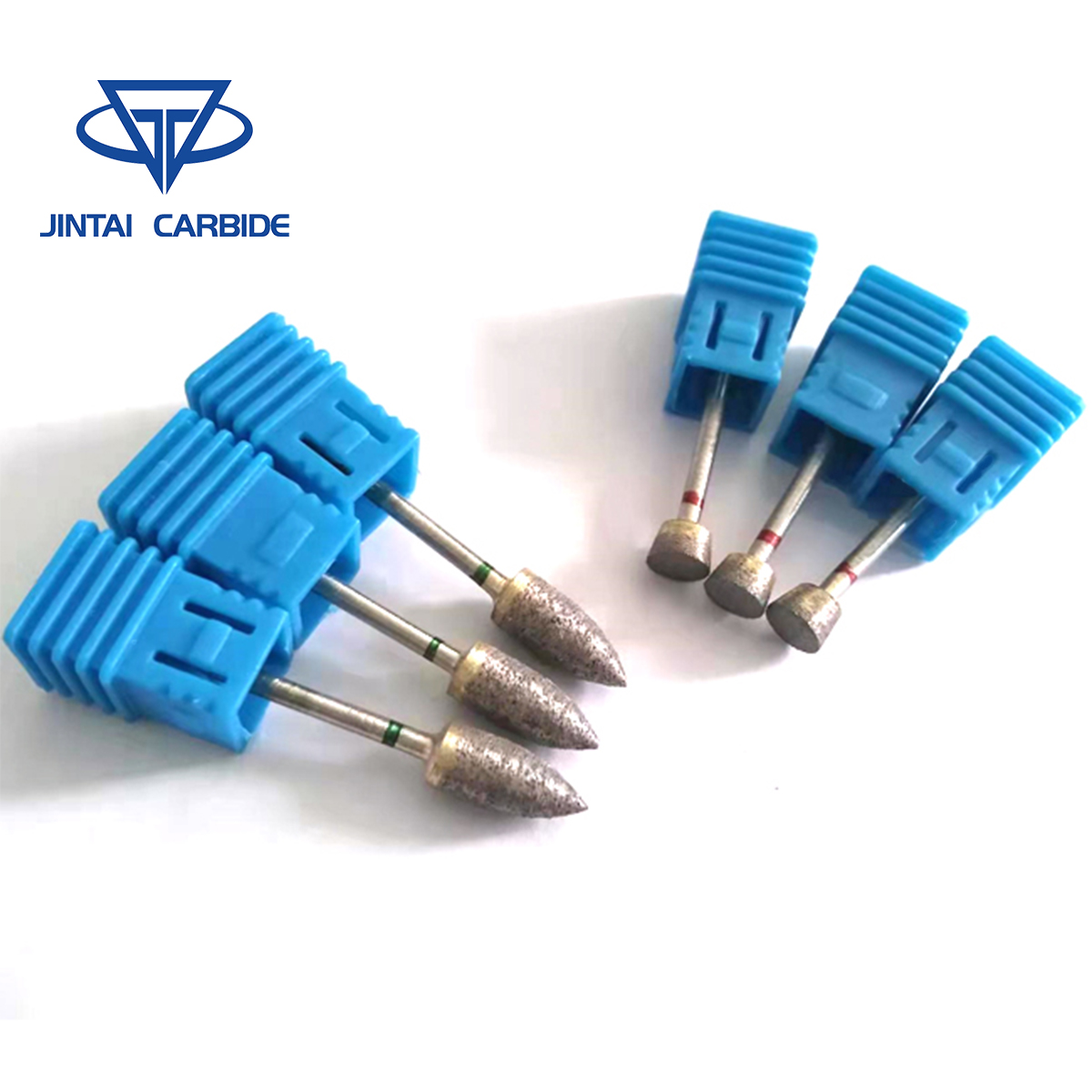

Ukunyathela Kufa Intloko Ebandayo

Iimbonakalo:

Khetha ibakala elifanelekileyo ngokusekwe kusetyenziso lwenyani lomthengi kunye nezinto ezilungiswayo.Ngamabakala ahlukeneyo e-tungsten steel stamping die, inokuhlangabezana neemfuno zezicelo ezahlukeneyo, iinkcukacha ezipheleleyo, imilinganiselo engenanto echanekileyo, ukunciphisa umthamo wokucubungula, kunye nokuphucula ukusebenza kakuhle ngelixa unciphisa iindleko.

Ukusebenza:

Ukusebenzisa i-99.95% yezinto ezicocekileyo ze-tungsten carbide powder kunye ne-cobalt, ubunzima bentloko ebandayo bufa bufikelela ngaphezu kwe-HRA88, amandla okugoba angaphezulu kwe-2400, ngokuqina okubomvu okugqwesileyo, ukumelana nokunxiba okuphezulu, imodyuli ephezulu, ukugoba okuphezulu, kunye nokumelana nefuthe elihlala ixesha elide. .

Usetyenziso:

Ifanele isihloko esibandayo kunye nokugqithiswa okubandayo kweendawo eziqhelekileyo ezenziwe ngobhedu, i-aluminiyam, intsimbi, izinto zentsimbi yealloyi, ezifana nezikrufu, iirivets, njl njl. kufa, intonga yokunciphisa iyafa, njl.

Ukumelana ne-Corrosion kubalulekile xa kuziwa ekugcineni umgangatho womphezulu kunye nokusebenza okuhlala ixesha elide.I-tungsten carbide yethu iyafa yenzelwe ngokukodwa ukuxhathisa ngokufanelekileyo ukubola.Ezi ntlobo zokubumba zixhathisa ngokungaqhelekanga kumhlwa kwaye ziya kugcina umphezulu wakho ukwimeko ecocekileyo, uqinisekisa ukugqitywa okugqibeleleyo ngalo lonke ixesha.Unokuzithemba iimolds zethu ukuba zime kuvavanyo lwexesha kwaye zizise iziphumo ezigqwesileyo ngalo lonke ixesha.

Nokuba luyilo olukhethekileyo, ubungakanani obukhethekileyo okanye iimfuno ezithile zokusebenza, iqela lethu leengcaphephe lizinikele ekuziseni ukubumba okungaphaya kokulindela kwakho.

Ukumelana ne-Corrosion kubalulekile xa kuziwa ekugcineni umgangatho womphezulu kunye nokusebenza okuhlala ixesha elide.I-tungsten carbide yethu iyafa yenzelwe ngokukodwa ukuxhathisa ngokufanelekileyo ukubola.Ezi ntlobo zokubumba zixhathisa ngokungaqhelekanga kumhlwa kwaye ziya kugcina umphezulu wakho ukwimeko ecocekileyo, uqinisekisa ukugqitywa okugqibeleleyo ngalo lonke ixesha.Unokuzithemba iimolds zethu ukuba zime kuvavanyo lwexesha kwaye zizise iziphumo ezigqwesileyo ngalo lonke ixesha.

Nokuba luyilo olukhethekileyo, ubungakanani obukhethekileyo okanye iimfuno ezithile zokusebenza, iqela lethu leengcaphephe lizinikele ekuziseni ukubumba okungaphaya kokulindela kwakho.

Vula ubuchule obuchanekileyo beTungsten Carbide Molds!Njengomntu owela umda we-e-commerce connoisseur, ufikile kwindawo egqibeleleyo yokungunda iTungsten Carbide Molds egqwesileyo kwizicelo zokubumba ezahlukeneyo, iqinisekisa ukuchaneka okungenakuthelekiswa nanto kunye nokuqina.

Yenziwe ngobuchwephesha ngobuchwephesha obungenakulinganiswa nanto, iTungsten Carbide Molds yethu ibonisa ubulukhuni obungaqhelekanga kunye nokunganyangeki kokunxiba, nto leyo ebenza ukuba babe lolona khetho lubalaseleyo kwimisebenzi yokubumba kumashishini afana neemoto, i-elektroniki, nokunye.Themba ezi zingundo ukuze zinikeze iziphumo ezingenasiphako kunye nobomi obude, ukuguqula iinkqubo zakho zokubumba.

Ngaphandle kokuqina kwazo okungaqhelekanga, iiTungsten Carbide Molds zethu zibonisa ukumelana nobushushu okumangalisayo, ziqinisekisa ukusebenza okungaguqukiyo naphantsi kwezona meko zinzima kakhulu zobushushu obuphezulu.Amava amandla abo okugcina iimilo ezichanekileyo kunye nokuthembeka, okukunika amandla okwandisa imveliso kunye nokunciphisa iindleko zemveliso.

E-JINTAI, siyazingca ngokuzisa iimveliso ezidlula imigangatho ephezulu yomgangatho.I-Tungsten Carbide Mold nganye ivavanywa ngokungqongqo, iqinisekisa ukufana kunye nokugqwesa, ikuvumela ukuba ufezekise iziphumo ezigqwesileyo kwiiprojekthi zakho zokubumba.

Yamkela ukusebenza kakuhle kunye nokuphumelela kweendleko ngeprimiyamu yethu yeTungsten Carbide Molds, kwaye ufumane umda wokukhuphisana kwishishini lakho.Sebenzisana nathi namhlanje ukuze ube namava okusebenza ngokungenakuthelekiswa nanto oku kuziswa koku ngundo kwimisebenzi yakho yokubumba.

Khetha i-JINTAI yokuthembeka, ukusebenza okuphezulu kweTungsten Carbide Molds, kwaye ubone amandla abo okwenyani ekunyuseni ishishini lakho libe phezulu.Beka iodolo yakho ngoku kwaye usebenzise amandla ezisombululo zethu zokubumba ezikumgangatho ophezulu.

Uluhlu lweBanga

| IBanga | ISO Code | iiPropathi zoomatshini boMzimba (≥) | Isicelo | ||

| Ukuxinana g/cm3 | Ukuqina(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining yentsimbi kunye neentsimbi ezingenayo i-ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Ilungele ukuchaneka kwe-machining kunye nokugqitywa kwesiqingatha sentsimbi etyhidiweyo kunye neentsimbi ezingenayo i-ferrous, kunye nokulungiswa kwentsimbi yemanganese kunye nentsimbi ecinyiweyo. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Ilungele ukugqitywa kwe-semi-ukugqiba kunye ne-rough machining yentsimbi etyhidiweyo kunye ne-alloys ekhanyayo, kwaye ingasetyenziselwa ukucwangciswa kwentsimbi kunye nentsimbi ephantsi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Ifanelekile ukugrumba ilitye elijikelezayo kunye ne-rotary impact drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Ifanele ukulayita okumile okwetshizili okanye amasuntswana amazinyo angama-conical koomatshini bokwemba amatye obunzima bokujongana nokwakheka kwamatye aqinileyo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Ifanelekile ukuvavanywa kwe-tensile yeentsimbi zetsimbi kunye nemibhobho yensimbi phantsi koxinzelelo oluphezulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Ilungele ukwenza isitampu iifa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Ilungele ukwenza isitampu esibandayo kunye nokucofa okubandayo kumashishini anje ngeendawo eziqhelekileyo, iibheringi, izixhobo, njl. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yensimbi engenasici kunye nentsimbi ye-alloy jikelele. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Ifanelekile kwi-semi-finishing yensimbi engenasici kunye nentsimbi ephantsi ye-alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Ifanelekile ukuchaneka kwe-iron-based based, i-nickel-based high-temperature alloys, kunye nentsimbi ephezulu. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Ifanelekile ukusika intsimbi enzima kunye nentsimbi. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Ifanelekile ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Ilungele ukuchaneka kwe-machining kunye ne-semi-finishing yentsimbi kunye nentsimbi yokuphosa, kunye nesantya sokutya esiphakathi.I-YS25 yenzelwe ngokukodwa imisebenzi yokugaya kwintsimbi kunye nentsimbi. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Ilungele izixhobo zokusika ezinzima, ezibonelela ngeziphumo ezigqwesileyo ekujikeni ngokurhabaxa kwe-castings kunye neentlobo ezahlukeneyo zentsimbi. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Ifanele ukulayita amasuntswana okugrumba amatye ajikelezayo kunye nokugrumba kulwakhiwo oluqinileyo noluqina noko. |

Inkqubo yoku-odola

Inkqubo yeMveliso

Ukupakishwa